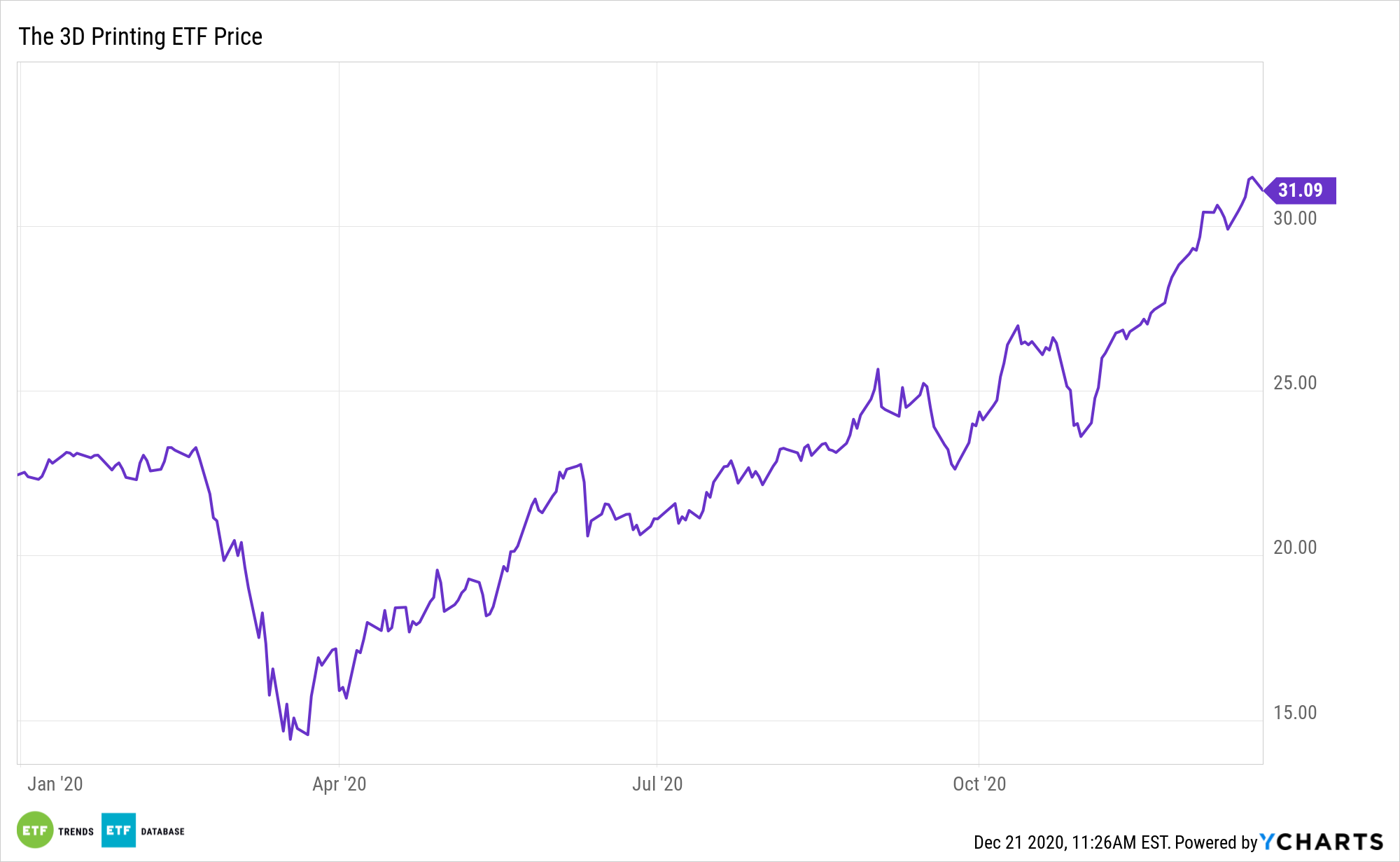

Somewhat quietly, the 3D Printing ETF (CBOE: PRNT) is continuing its 2020 with a 16.50% gain over the past month that’s elevated the exchange traded fund’s year-to-date gain to north of 40%.

Passively managed PRNT offers leverage to its namesake as its benchmark “is composed of equity securities and depositary receipts of exchange-listed companies from the U.S., non-U.S. developed markets and Taiwan that are engaged in 3D printing-related businesses within the following business lines: (i) 3D printing hardware, (ii) computer-aided design (“CAD”) and 3D printing simulation software, (iii) 3D printing centers, (iv) scanning and measurement, and (v) 3D printing materials,” according to Ark.

3D printing, one of the original disruptive technologies, intersects with a variety of industries and its materials applications could bode well for PRNT’s long-term trajectory.

“The market for 3D printing materials has been affected by the COVID-19 pandemic, but plenty of market drivers point to a strong future. Indeed, IDTechEx forecasts that the global market for 3D printing materials will be worth $18.4 billion in 2030,” reports Cheslsey Drysdale for Printed Circuit & Design Fab, citing the IDTechEx report, “3D Printed Materials Market 2020-2030: COVID Edition.”

3D Printing Is Slowly Expanding Its Grip on Manufacturing Materials

PRNT debuted nearly three years ago as the first US-listed ETF dedicated to the 3D printing theme. The fund is one of two passively managed products from New York-based Ark Investment Management. ARK believes 3D printing will revolutionize manufacturing by collapsing the time between design and production, reducing costs, and enabling greater design complexity, accuracy, and customization than traditional manufacturing.

“3D printing in both domestic and industrial settings has boomed since the fused deposition printing process came off patent in 2009, and commercial 3D printing undertaken in factories and by 3D printing bureaus is now an established industry vertical,” according to Printed Circuit. “While these end-users initially produced mostly prototypes or items for product development, their scope has increased greatly in the past few years, and we now see 3D printing moving into mainstream manufacturing and onto production lines. This is due to significant, recent evolution in printers and printer consumables.”

One of the traits that makes PRNT a compelling long-term idea is the sheer expanse of industry-level applications for 3D printing. What’s more important than the recent strength in PRNT is that there’s an increasingly strong long-term case for the 3D printing needs.

“The facts that 3D printing is highly customizable and can be undertaken locally are also strengths in markets that increasingly demand these,” reports Printed Circuit. “For example, at the start of the COVID-19 pandemic, when healthcare was crying out for effective PPE and medical consumables, responses often came from relatively small, local companies using 3D printing to make bespoke masks, swabs, and valves for CPAP machines. The need for bespoke solutions is not restricted to critical applications; customization is sought in retail, too.”

For more on disruptive technologies, visit our Disruptive Technology Channel.

The opinions and forecasts expressed herein are solely those of Tom Lydon, and may not actually come to pass. Information on this site should not be used or construed as an offer to sell, a solicitation of an offer to buy, or a recommendation for any product.