By Alex Owen-Hill

As we dismantle the many conveyor belts and put the UR e-Series back in their boxes, here’s what we learned over this action-packed 3 days.

The Robotiq User Conference is over for another year. It’s time for us to tidy up the Voltigeurs de Québec Armoury, pack all these shiny UR robots into their boxes, and start to think about what we can do at next year’s RUC!

While the team gets out their tools to dismantle the challenge workstations, here’s a recap of what we’ve learned through this year’s RUC.

Cobots are Truly Gaining Traction

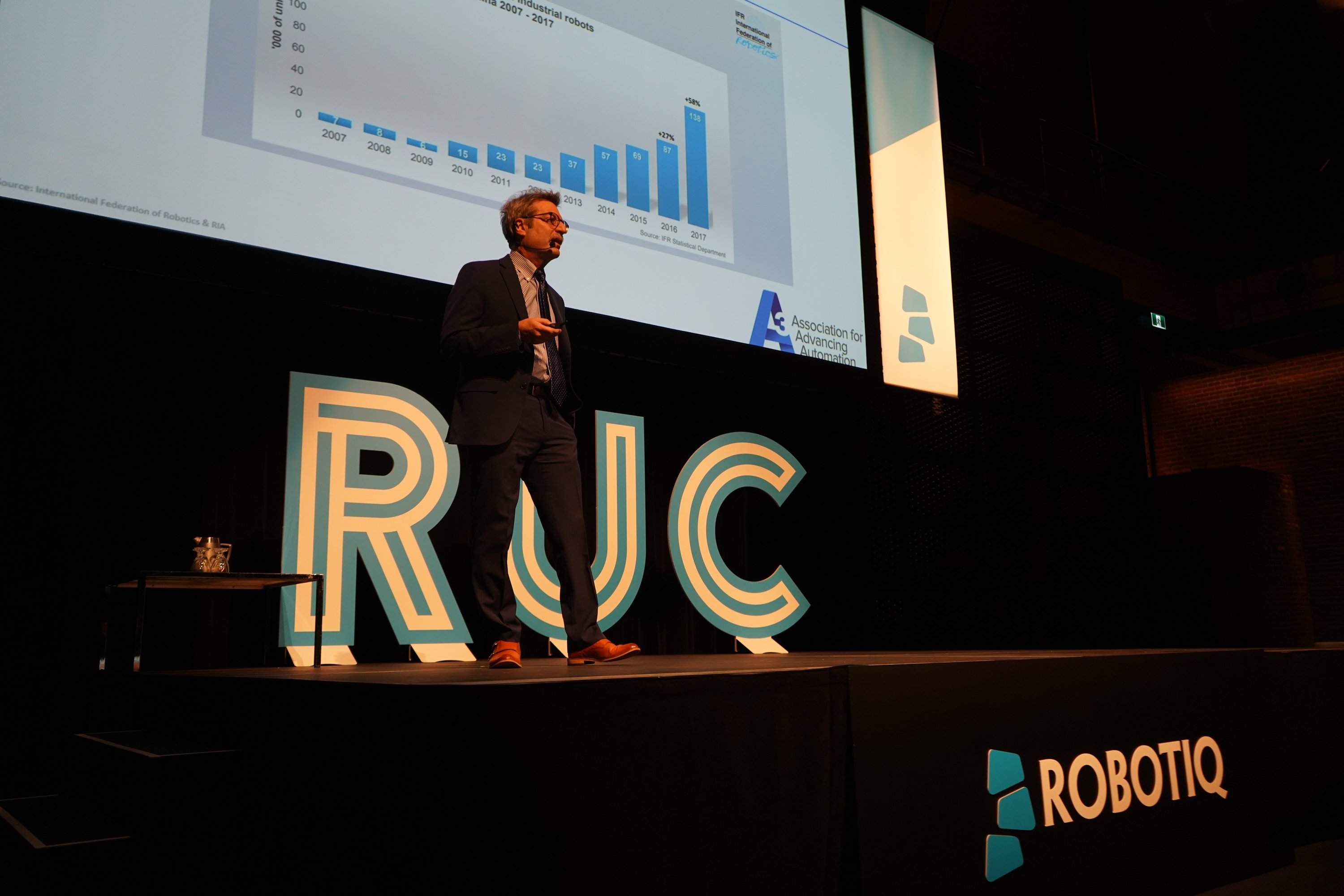

We started this year’s RUC with some potentially surprising news. A3’s Jeff Burnstein revealed in his keynote that nobody really knows big the cobot industry is, or how much it’s going to grow.

![]()

However, although the size of the market is a mystery, it looks certain that the market is growing.

Not only are cobots becoming more popular. According to our attendees, they can achieve some tasks that traditional industrial robots simply can’t do… like the task that we set participants of this year’s RUC technical challenge.

As Xavier Quintero from HTL told us last night:

“When I saw the challenge I thought “Wow! It’s going to be very difficult.” Because it’s a process that only a human can do. I know that only a cobot could do it. An industrial robot can’t do a process like this.”

Safety: Is it Too Much or Not Enough?

Safety has come up several times throughout RUC this year. Almost all of our keynote speakers on Wednesday mentioned the safety of cobots at least once.

Jeff Burnstein told us about a time when he almost lost the use of his hand thanks to a cobot and talked about the vital need to do risk assessments with cobots. Even though they are designed to be safe, he said, cobots are not inherently safe in all situations. For example, what would happen if a cobot was holding a knife?

Mark Kahwati from UR replied: Well Jeff, with the safety sphere feature of our new e-Series robots, you could give a knife to the robot and it could still be safe. He also explained how the programmable stopping time and distance in the new robots will make risk assessments easier.

Eben Ostergaard from UR, in his discussion with Samuel Bouchard, said that he believes the safety limits of modern cobots are “super-conservative, bordering on the ridiculous.” However, he thinks that this high level of caution is probably necessary to gain wider acceptance of cobots.

Are cobots too safe or not safe enough? We’ve not come to any conclusions, but some very interesting discussion points have been raised during this year’s RUC.

Start Production Fast: Lean Robotics in Action

We’ve truly seen the lean robotics framework in action here at RUC 2018. In Samuel’s keynote, he explained the three stages of the framework: Design, Integrate, and Operate. He encouraged the attendees to focus on the lean robotics tagline: Start Production Faster — something which would soon become important once the technical challenge began.

Then, the teams got hands-on with the robots. Following Jean-Philippe Jobin’s entertaining demo, the 10 teams in the technical challenge all got the opportunity to learn how to use the new Robotiq products and the new UR e-Series robots.

At the same time, the sales teams attended a workshop which would prepare them for the sales challenge ahead.