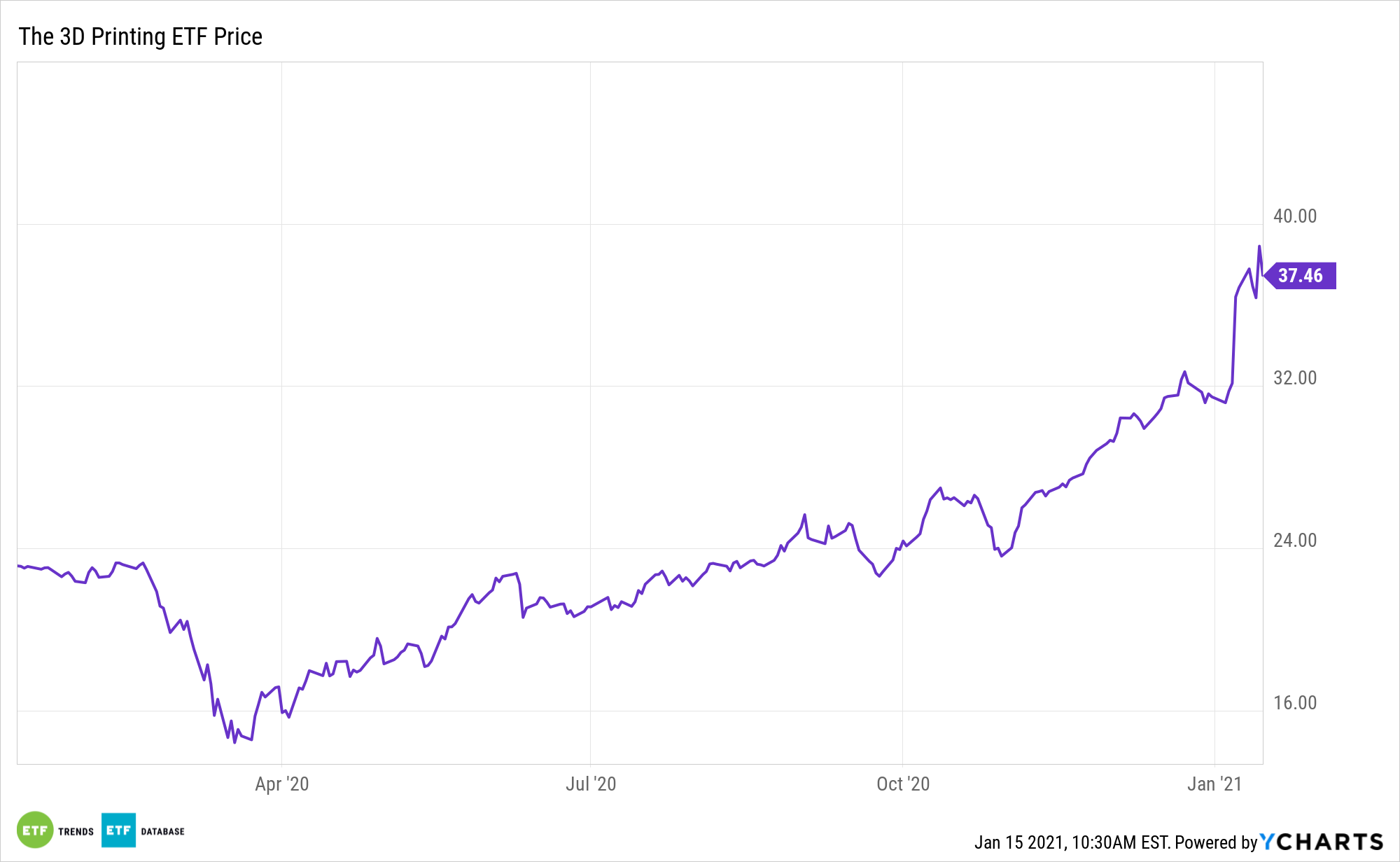

3D printing was the original disruptive technology of the 21st century. It’s roaring back in quiet fashion as highlighted by the ARK 3D Printing ETF (CBOE: PRNT).

PRNT debuted nearly three years ago as the first US-listed ETF dedicated to the 3D printing theme. The fund is one of two passively managed products from New York-based Ark Investment Management. ARK believes 3D printing will revolutionize manufacturing by collapsing the time between design and production, reducing costs, and enabling greater design complexity, accuracy, and customization than traditional manufacturing.

Passively managed PRNT offers leverage to its namesake as its benchmark “is composed of equity securities and depositary receipts of exchange-listed companies from the U.S., non-U.S. developed markets and Taiwan that are engaged in 3D printing-related businesses within the following business lines: (i) 3D printing hardware, (ii) computer-aided design (“CAD”) and 3D printing simulation software, (iii) 3D printing centers, (iv) scanning and measurement, and (v) 3D printing materials,” according to Ark Investment Management.

3D Printing Is Changing the Game

When 3D printing initially emerged, industrial AM machines were highly expensive and painstakingly slow. That narrative is changing.

“These machines, however, have made huge advancements in terms of cost, speed and ability since 2013, to the point where they are now capable of quickly and cost-effectively mass-producing metal end-use parts on the factory floor,” reports InvestorPlace.

3D printing, one of the original disruptive technologies, intersects with a variety of industries. Its materials applications that could bode well for PRNT’s long-term trajectory. Plus, 3D printing will play an integral role in the fourth industrial revolution.

“Because the emergence of Industry 4.0 has raised the standard for customization and automation in the world’s supply chains. That is, tomorrow’s supply chains will need to be automated (to save on labor costs) and need to be able to produce customized parts (to meet growing consumer demand for custom products),” adds InvestorPlace. “As it turns out, AM is particularly good at customization and automation. You can make any design you want in a software program, send it to the 3D printer and the printer can produce that design — all without needing any human labor on the manufacturing side.”

For more on disruptive technologies, visit our Disruptive Technology Channel.

The opinions and forecasts expressed herein are solely those of Tom Lydon, and may not actually come to pass. Information on this site should not be used or construed as an offer to sell, a solicitation of an offer to buy, or a recommendation for any product.